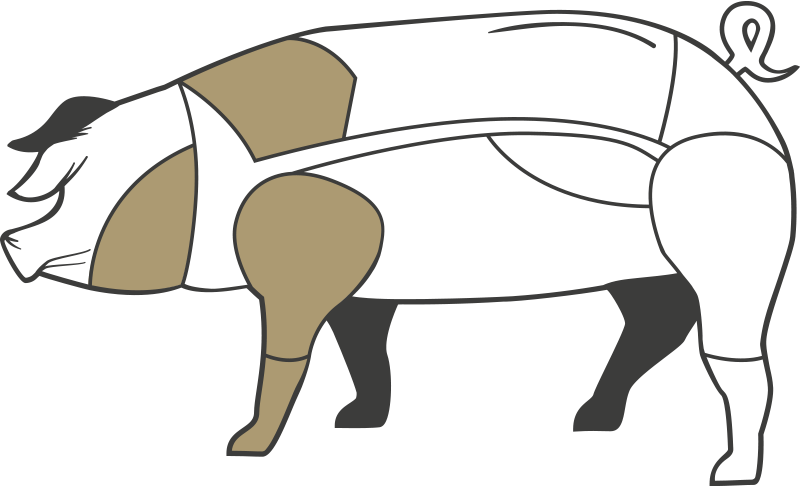

FORE-END.

The sow fore-end includes the shoulder, the jowl, the collar or the riblet

At Le Porc Gourmet S.A. we are specialized in pork slaughtering and sow deboning using the most modern technologies. Our deboning room is equipped with the latest technologies which meet the highest control and quality standards.

As a part of Grupo Jorge, leaders in the pig industry, we can guarantee the best quality, full traceability, and food safety on all of our products.

At Le Porc Gourmet S.A. we are specialized in pork slaughtering and sow deboning using the most modern and innovative facilities which grands us the possibility of offering the highest quality and food safety. With more than 20 years of experience in sow meat we can guaranty a high level of experience that comes from more than 4 generations of specialized professionals in the pig industry.

We are part of Grupo Jorge, European and World-wide leaders in the pig industry, with a great advantage in the national and international meat sector, with more than 80% of our sales for export. Carcasses arrive directly from Le Porc Gourmet S.A. own slaughter house connected to Grupo Jorge, guarantying food safety and high quality thanks to an uninterrupted cold chain.

Le Porc Gourmet S.A. controls it own production chain, starting with pork selection and genetics, producing our own animal food, we have our own breading and growing farms, our own slaughter houses, deboning rooms, elaborating our own products and sub-products, our own cold storage facilities and logistics company. With all this, Le Porc Gourmet S.A. can guarantee perfect and complete traceability strictly maintaining the cold chain resulting in premium quality products.

LE PORC GOURMET S.A. exports pork meat and it by-products to the foreign market, counting for this with the corresponding authorizations to export to Europe, Asia, Africa, South America, and North America.

Our sow deboning room is equipped with the latest of technologies which allows us to have a high level of automation and control, offering high quality products maintaining high productivity.

We work with an ultramodern automation system which is key to obtain a constant and balanced production. All this process being technically controlled while also being able to adapt to all our client’s requirements and cuts.

All the animals arrive at Our modern slaughter house which is also part of Grupo Jorge’s cutting plant.

The carcasses are passed through our shock cooling tunnel and are stored in our stabilization cold storage after being slaughtered to maintain all the meat properties.

The carcasses are cut and deboned after 24h by specialized professionals caring about yield and food quality.

After deboning the meat which is sold fresh is stored in 0º Celsius storages to protect all of its properties.

The meat is sold frozen: 24 hours after freezing the product is palettized in a temperature-controlled room to maintain the meat properties.

The product will be stored in our modern -20 º Celsius cold storage with room for 1700 pallets and automatic controlled temperature.

Our retail department has specialized salesmen that own a wide meat knowledge and understand all the products.

Grupo Jorge´s own transport and logistics company, guarantees the perfect transportation of either fresh and frozen products without interrupting the cold chain.

Grupo Jorge and all its companies cover all the processes in the pork industry like genetic selection, animal food production, fattening, slaughtering, deboning, cooling, transportation. In our production line at Le Porc Gourmet S.A. we guaranty quality, traceability, control and food safety of the pork meat.

All our cutting and deboning processes are done by specialized professionals that have been with us during all these years of experience in this sector. Our careful cold chain preservation, the experienced professionals, the modern facilities and the traceability prove the perfect conservation of the product and all its organoleptic qualities.